High Intensity Thermal Exchange through Materials, and Manufacturing Processes

Program Description:

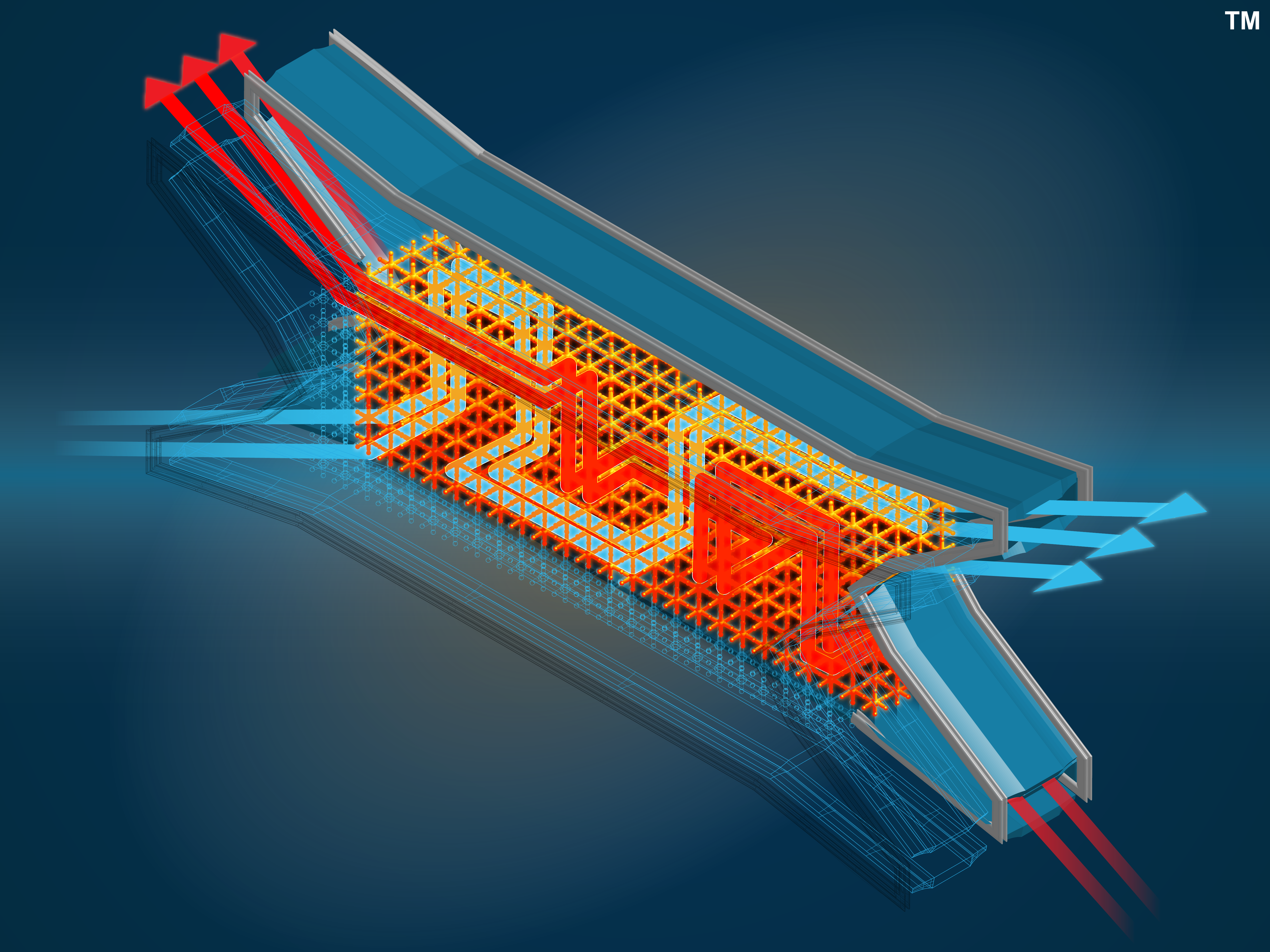

The projects that comprise ARPA-E’s HITEMMP (High Intensity Thermal Exchange through Materials and Manufacturing Processes) program will develop new approaches and technologies for the design and manufacture of high temperature, high pressure, efficient, and highly compact heat exchangers. Heat exchangers are critical to efficient thermal energy exchange in numerous industrial applications and everyday life, with valuable applications in electricity generation, transportation, petrochemical plants, waste heat recovery, and much more. HITEMMP projects target heat exchangers capable of operating for tens of thousands of hours in temperatures and pressures exceeding 800°C and 80 bar (1,160 psi) respectively. This new class of hardware, designed and manufactured using novel techniques, topologies, and materials, would enable far greater exchanger efficiency, thus boosting the performance of many important industrial processes.

Innovation Need:

Most heat exchangers today are limited in performance and efficiency by two important factors. The structure of these devices limits maximum heat transfer rates, or how quickly thermal energy moves from the “hot side” to the “cold side” of the exchanger. Secondly, integration of the heat exchanger into its surrounding system often introduces performance limitations that prevent the device from achieving maximum efficiency.

To overcome these challenges, HITEMMP project teams must develop new exchanger topologies, or physical designs, that optimize device structure with suitable advanced materials and the fluids flowing through them for the desired range of operating conditions. Equally important is the further refinement of existing, or the development of new, manufacturing technologies that enable attractive performance at an acceptable cost. If successful, durable and affordable higher-temperature heat exchangers could lead to substantially higher power conversion efficiencies that in turn could reduce fuel consumption, system footprint (and thus capital and operation costs), and CO2 and nitrogen oxide emissions.

Potential Impact:

If successful, HITEMMP projects will enable a revolutionary new class of heat exchangers with applications for commercial and industrial energy producers and consumers across the economy.

Security:

High performance, efficient heat exchangers could increase industrial efficiency, potentially reducing energy imports and supporting domestic industries.

Environment:

More efficient electricity generation and industrial processes could significantly reduce related sector emissions.

Economy:

HITEMMP technologies could reduce the amount of fuel needed to generate electricity and the energy to power many industrial processes, reducing cost and improving efficiency.

Contact

Project Listing

• CompRex - Compact Heat Exchanger for High Temperature High Pressure Applications Using Advanced Cermet

• General Electric (GE) Global Research - Ultra Performance Heat Exchanger Enabled by Additive Technology (UPHEAT)

• International Mezzo Technologies - A 2-5 MW Supercritical CO2 Micro Tube Recuperator: Manufacturing, Testing, and Laser Weld Qualification

• Massachusetts Institute of Technology (MIT) - Multiscale Porous High-Temperature Heat Exchanger Using Ceramic Co-Extrusion

• Michigan State University (MSU) - Heat-Exchanger Intensification through Powder Processing and Enhanced Design (HIPPED)

• Michigan Technological University (MTU) - High-density SSiC 3D-printed Lattices for Compact HTHP Aero-engine Recuperators

• Thar Energy - Recuperated Supercritical Carbon Dioxide Brayton Power Cycle System

• The Boeing Company - Highly Compact Metallic Heat Exchangers for Extreme Environments

• United Technologies Research Center (UTRC) - Additive, Topology-Optimized Ultra-Compact Heat Exchanger

• United Technologies Research Center (UTRC) - Low-Cost Glass Ceramic-Matrix Composite Heat Exchanger

• University of California, Los Angeles (UCLA) - SHOTEAM: Superalloy Heat exchangers Optimized for Temperature Extremes and Additive Manufacturability

• University of Maryland (UMD) - Additively Manufactured High Efficiency and Low-Cost sCO2 Heat Exchangers

• University of Missouri - UHT-CAMANCHE: Ultra-High Temperature Ceramic Additively Manufactured Compact Heat Exchangers

• Vacuum Process Engineering (VPE) - Compact Diffusion Bonded Printed-Circuit Heat Exchanger Development Using Nickel Superalloys for Highly Power Dense and Efficient Modular Energy Production Systems