General Electric Company (OPEN 2012)

BACK TO THE FUTURE, FOR THE ELECTRIC POWER GRID

UPDATED: FEBRUARY 3, 2017

PROJECT TITLE: High-Voltage, High-Power Gas Tube Technology for HVDC Transmission

PROGRAM: OPEN 2012

AWARD:$7,206,569

PROJECT TEAM: General Electric Company (Lead), University of Wisconsin, Princeton Plasma Physics Lab

PROJECT TERM: April 2013 – April 2017

PRINCIPAL INVESTIGATOR (PI): Dr. Timothy J Sommerer

TECHNICAL CHALLENGE

Direct current (DC) electric power transmission is an enabling technology for improved security of the electric power system through long distance power transmission, connecting asynchronous grids, and integration of renewable energy onto the grid. The cost per mile of a traditional high-voltage alternating current (HVAC) overhead line is 25-100% higher than a corresponding high voltage DC (HVDC) line. However, DC power transmission requires that generated AC power be rectified to DC for transmission, and then inverted back to AC for customers. Existing AC-DC power conversion equipment is mature but expensive, limiting the beneficial use of DC systems. A more cost-effective conversion technology is needed.

TECHNICAL OPPORTUNITY

Physical gas tube devices – gas-tight assemblies of metal electrodes and ceramic insulators – were the original means for high-voltage grid-scale AC-DC power conversion. They were displaced by power semiconductors because of their superior reliability and lower maintenance requirements. A disadvantage of power semiconductors is that their voltage-handling capability is modest (<10 kV) in view of the system voltage requirements (>300 kV). The high cost of present AC-DC converter equipment is caused in part by the complexity of stacking semiconductor power electronic devices in series to control very high system voltages. The trend is to even greater system complexity, as system voltages rise faster than device voltages, and systems are extended to applications with weak or nonexistent AC grids (e.g., offshore). However, tube devices have continued to be the technology of choice for demanding applications like x-ray tubes for medical imaging and microwave power tubes for satellite communications. Decades of technology development in those fields have led to vast improvements in tube reliability and performance. Thus, there is the opportunity to “go back to the future” and develop a modern gas tube for grid-scale power conversion.

INNOVATION DEMONSTRATION

The goal of this project is to develop a long life, high-voltage switching gas-plasma tube, capable to >300 kV. To achieve this goal the team has accomplished three major tasks, namely, the development of non-mercury liquid cathode and plasma, the scaling of device voltage, and the use of a low-loss mode of operation.

The first key component to the project approach is a self-healing liquid metal cathode. Even with all the advances in tube technology, physical damage to the cathode (negative electrode) is still expected to unacceptably limit device life for grid applications. The project’s approach is to replace the conventional solid metal cathode with a liquid metal cathode, with the idea that liquid metal can reflow and self-heal from some damage, and it can be pumped and replenished if necessary. The project team demonstrated that a liquid metal cathode could operate at the high current density (5 A/cm2) required for grid applications, based on the technological developments that now underpin the use of liquid metal bearings in some high-voltage x-ray tubes.

A second focus of the project is the scaling of device voltage. A crossed field (electric and magnetic field) device design was selected as the starting point, and the team has built and operated such devices to 100 kV. Device testing within the project is limited by power considerations to single-pulse operation. The team is now constructing and expecting to demonstrate operation of a 300 kV device and to estimate the upper limit of the operating voltage for this technology.

During the project, the team found that the tube can operate in a unique low-loss, low-voltage mode that could have great benefits for both life and efficiency. The device efficiency improves as the device dissipates less power during on-state with the lowered forward voltage. The device reliability improves since the wear-out mechanism of the cathode is exponentially dependent on the forward voltage.

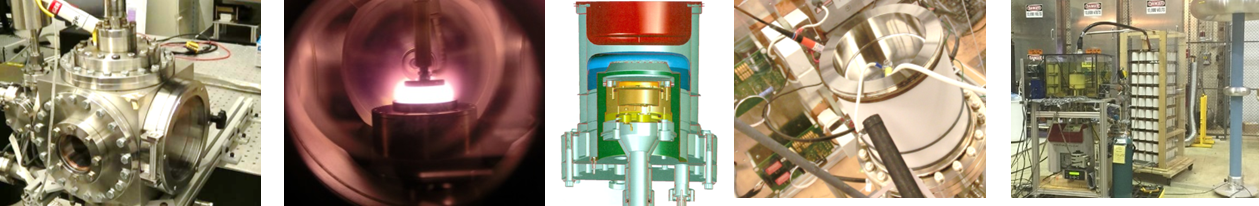

Montage of experimental work performed within the current Project. (a) ‘Benchtop’ system for liquid cathode development; (b) interior of Benchtop system during conduction phase operation; (c) Gas Switch device cut-away; (d) Gas Switch with Power Electronic Controls in background; (e) 300 kV test facility used for 100 kV Switch testing (Switch is immersed in yellow transformer oil, capacitor bank is in the background).

The team evaluated several system topologies to estimate the cost, efficiency, and size of a system for long-distance DC transmission by overhead wires. For the base case (3 GW, 500 miles) the team found that the AC-DC conversion equipment cost could be halved if the tube operating voltage could be increased to 300 kV. An important part of the cost savings arises because the system topology produces a cleaner AC waveform, and less filtering is needed.[1] The efficiency of the system is expected to be competitive with, or even slightly better than, the best thyristor-based systems.

PATHWAY TO ECONOMIC IMPACT

General Electric develops and sells HVDC systems through its Grid Solutions business, which is initiating work in 2017 to build appropriate controls for a tube operation in a test-system environment, toward the goal of full-speed “burst” operation and testing. If successful, further tube testing will be done on a circulating power facility capable of sustained full-speed operation, prior to the construction of a larger-scale demonstrator system. There is still at least five years of work to be done to move the technology from the laboratory onto the grid.

In the shorter term, gas tubes might be a good candidate for high-voltage protection devices on AC transmission lines. Niche markets such as this are useful for gaining field experience with the gas tube. In the longer term the small size and light weight of gas-switch tubes may have large benefits for specialized applications such as offshore AC-DC converters, which can be the size of oil platforms, and for city center cable in-feeds, where real estate is at a premium. Gas-switch tubes can be part of a hybrid DC circuit breaker, a device that is complex and costly at this time, but is required for the emergence of a true DC grid.

LONG-TERM IMPACTS

The gas tube technology developed and demonstrated in this project is expected to reduce overall HVDC terminal cost by 40%, potentially reducing the economically advantageous HVDC transmission distance relative to traditional AC infrastructure from 500 miles to 250 miles. GE’s gas switches could also enable multi-terminal HVDC networks. Making HVDC transmission more economic could bolster new possibilities such as interties between regional grids for wider area balancing, and high-efficiency transmission corridors to reach remote areas with abundant solar or wind resources.

As there are currently no major power semiconductor manufacturers in North America due to high entry barriers and commoditized products, successful development of GE’s gas switch technology promises to create high quality jobs in the United States for system innovation, manufacturing, and deployment of high-efficiency HVDC transmission components and infrastructure.

INTELLECTUAL PROPERTY AND PUBLICATIONS

As of January 2017, the project has reported eight invention disclosures to ARPA-E, leading to seven patent applications and three issued patents.

Patents

Method and system for a gas tube switch-based voltage source high voltage direct current transmission system, US Patent 9,520,801

Systems and methods for regulating pressure of a filled-in gas, US Patent 9,330,876

Helium supply reservoir with fine dosing capability for an HVDC plasma switch, US Patent 9,557,009

The Project Team has also made numerous presentations of the scientific underpinnings of this technology at various scientific conferences, and has begun to publish findings in the open literature. The first publication is provided below:

Publications

Carlsson, J., Khrabrov, A., Kaganovich, I., Sommerer, T., & Keating, D. (2016). Validation and benchmarking of two particle-in-cell codes for a glow discharge. Plasma Sources Science and Technology, 26(1), 014003.

[1] Physics Today (Magazine): Kim Krieger, ‘A New Twist on an Old Technology’, 13 Aug 2014