ARPA-E Investor Update Vol. 13: Enzinc's EV Battery Anode

ARPA-E awardee Enzinc raised $4.5 million in seed funding for their zinc microsponge EV battery anode in a round led by Portland-based 3x5 Partners in July of 2022. This seed funding, along with a $1.8 million Bringing Rapid Innovation Development to Green Energy (BRIDGE) grant from the Electric Program Investment Charge (EPIC) program through the California Energy Commission (CEC), has allowed them to finalize testing of their prototype and design an automated production line for their anode. Alongside the $1.8 million BRIDGE grant, Enzinc has won four out of the five CEC grants within the EPIC Program, totaling $2.69 million.

Enzinc’s $450,000 award through ARPA-E’s Robust Affordable Next Generation Energy Storage Systems (RANGE) program back in 2014 helped develop their original zinc anode sponge, a 3-dimensional zinc structure with many micron-sized holes. The RANGE program seeks to enhance safety, maximize the overall energy stored in a vehicle, and minimize manufacturing costs.

“Receiving ARPA-E’s RANGE grant enabled us to work with the U.S. Naval Research Laboratory to develop a revolutionary zinc microsponge anode that makes powerful, safe and sustainable batteries for vehicles, buildings and energy microgrids,” said Michael Burz, Founder and CEO of Enzinc. “That initial award, along with the credibility that ARPA-E brings, set us on a path to take this innovation from the lab to a customer-focused product and to raise more than $8 million in private and public money. The end game is that any lead acid factory will be able to undergo a cost-effective capital upgrade and become a gigafactory building advanced batteries made with U.S.-mined materials to meet today’s demanding needs."

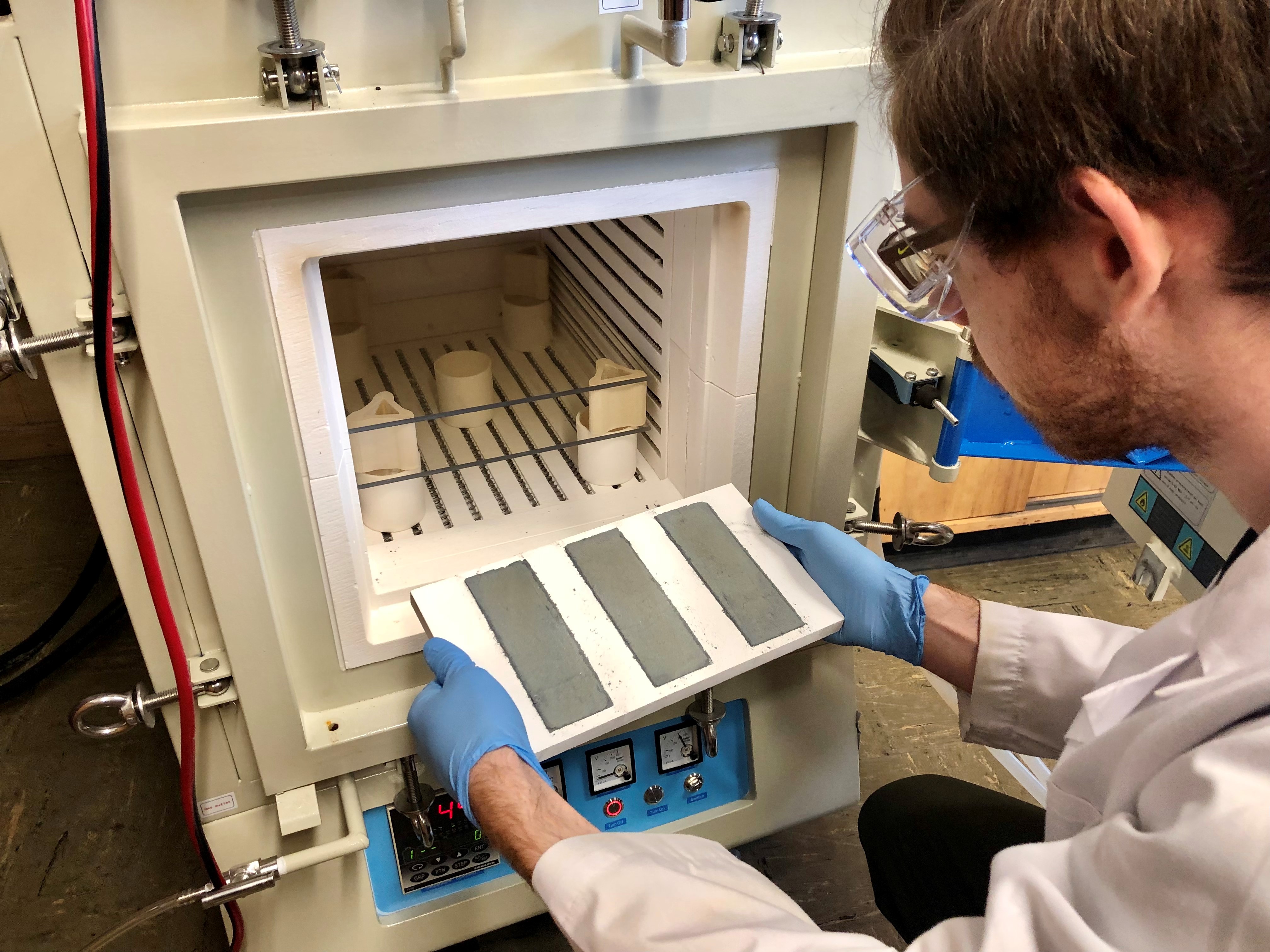

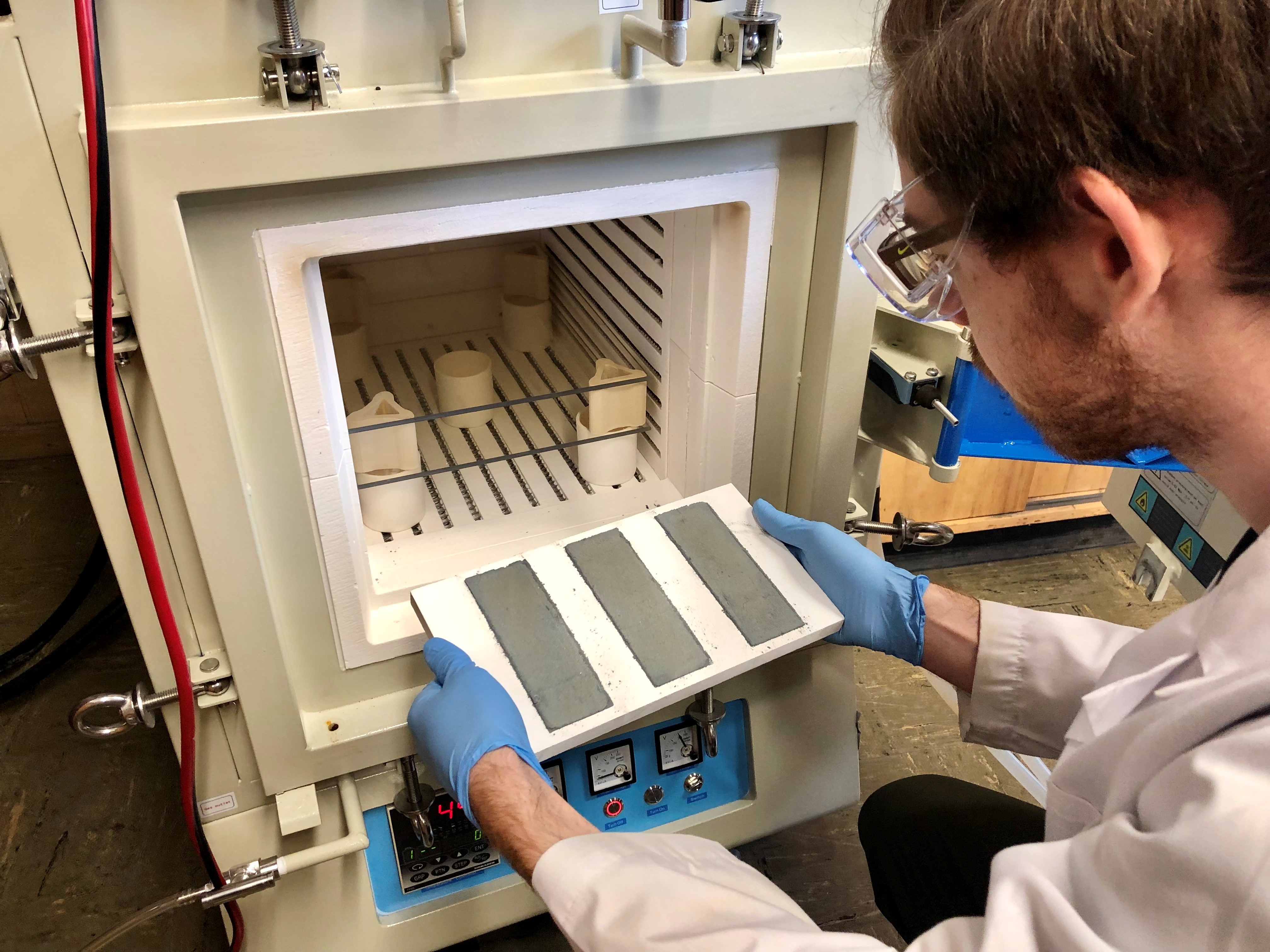

Enzinc CEO Michael Burz with Pilot Line Furnace

Lithium-ion batteries represent the status quo for EV battery chemistry because of their fast charging, high cycle life, and high-power density compared to traditional lead acid batteries. Depending solely on lithium-ion batteries to support the demand for EVs and the electrification of buildings and the grid, however, presents a serious challenge because lithium is scarce, expensive to source, and harmful to the environment to extract. New EV battery chemistries are necessary to improve the driving range, cost, and safety of EVs, thereby accelerating sustainable and widespread adoption of EVs.

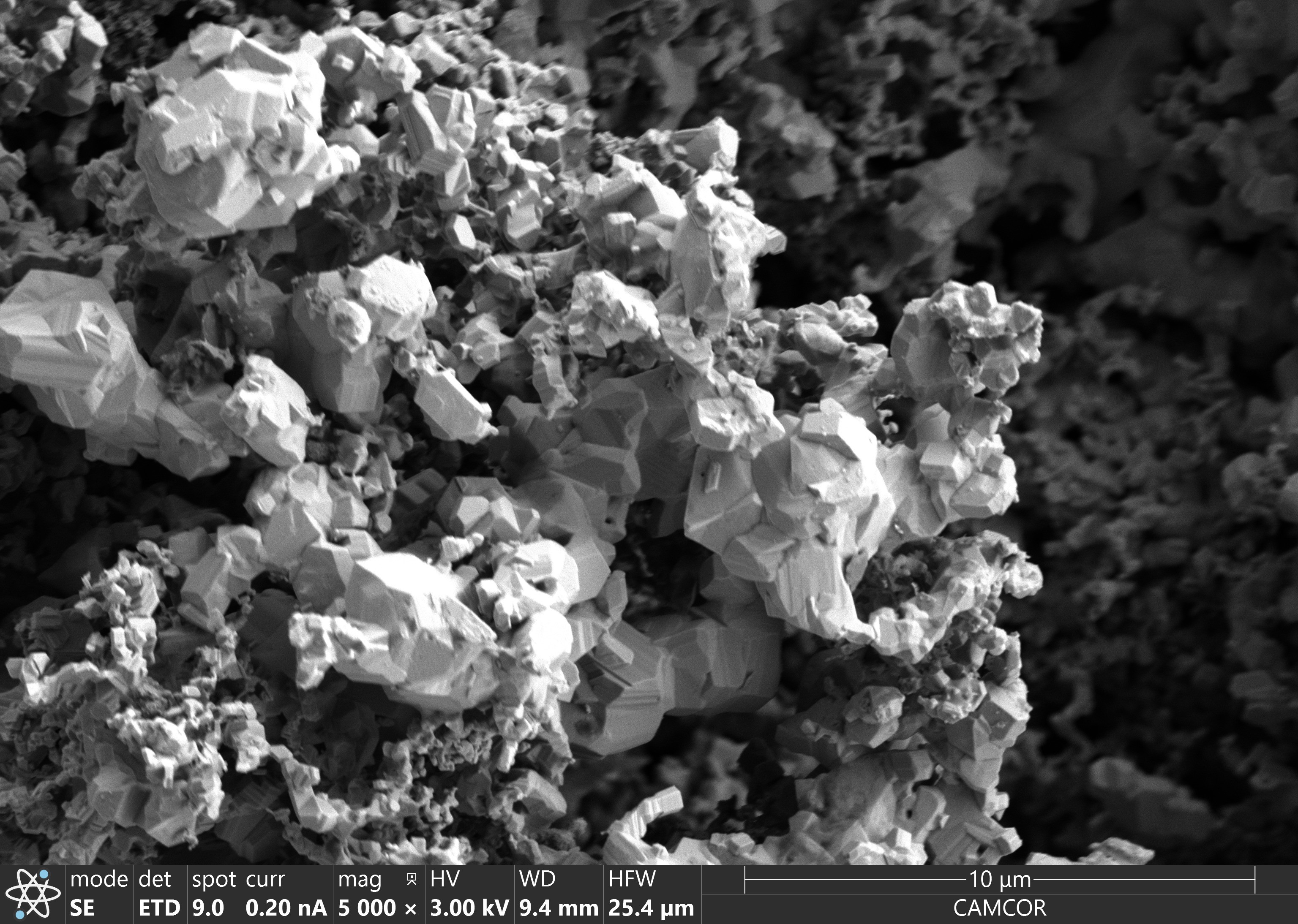

Zinc batteries provide one such alternative to lithium-ion batteries, but existing zinc-based batteries offer limited cycle life due to the potential for the formation of dendrites – crystalline structures that build up during charge and recharge cycles that can lead to battery shorts over time. To address this, Enzinc has developed a new technology that replaces conventional zinc powder-bed anodes with a porous zinc sponge that thwarts the formation of structures that lead to battery failure.

3D Scan of Fully Charged Zinc Microsponge

Enzinc’s technology could offer a safe, sustainable, and affordable option for the growing EV battery market. The use of widely available zinc alleviates supply chain concerns and affordability issues that surround lithium. It has no fire potential, no HVAC requirement, and a wide temperature range. Enzinc’s readily scalable technology taps into the $60 billion lead acid market as a player in the energy transition because existing lead acid manufacturing plants can be used for production of nickel-zinc batteries containing Enzinc’s zinc anode sponge. Enzinc’s technology makes zinc batteries viable for moderate-range EVs, such as e-bikes and delivery vehicles, as well as homes and commercial buildings.

Removing Anodes for Prototype Mobility Battery from Product Development Center Furnace

Enzinc received an exclusive license from the US Naval Research Laboratory to commercialize their zinc anode sponge technology. Enzinc has scaled their zinc anode by 124x from the initial coin cell testing to full scale commercial size anodes. They built an e-mobility battery and began testing in February of 2023. Enzinc has partnered with several international companies to demonstrate their ability to "drop-in" the zinc anode. They will convert existing legacy lead-acid battery factories into making a zinc-based batteries with 3x energy and 3x cycle life, tripling the batteries’ capacity.

Enzinc’s zinc anode sponge technology hopes to revolutionize the EV battery market by introducing a safe, sustainable option into the fold.