High Efficiency Split-Cycle Engine for Residential Generators

Technology Description:

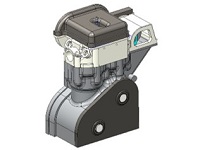

Tour Engine, in collaboration with Wisconsin Engine Research Consultants (WERC) will develop a miniature internal combustion engine (ICE) based on Tour's existing split-cycle engine technology. Traditional ICEs use the force generated by the combustion of a fuel (e.g. natural gas (NG)) to move a piston, transferring chemical energy to mechanical energy. This can then be used in conjunction with a generator to create electricity. Unlike a normal combustion engine, a split-cycle engine divides the process into a cold cylinder (intake and compression) and a hot cylinder (expansion and exhaust). This allows for independent optimization of the compression and expansion ratios, leading to increased thermal efficiency. A novel Spool Shuttle Crossover Valve (SSCV) is the key enabler for the Tour engine, as it transfers the fuel/air charge from the cold to hot cylinder.

Potential Impact:

If successful, Tour Engine’s project will facilitate development and commercialization of economical, efficient, and durable CHP systems for residential use. These advancements support progress toward ARPA-E’s overall goals as follows:

Security:

Innovations developed in this project could help households and businesses become more energy self-reliant and less susceptible to energy-related outages through distributed, local generation of power and heat.

Environment:

Widespread adoption of high-efficiency residential CHP systems could decrease overall primary energy consumption and therefore reduce CO2 emissions associated with electricity generation by up to 10%.

Economy:

Cost-effective NG-fueled residential CHP systems could offer consumers lower electricity and heating bills.

Contact

ARPA-E Program Director:

Dr. William Horak

Project Contact:

Dr. Oded Tour

Press and General Inquiries Email:

ARPA-E-Comms@hq.doe.gov

Project Contact Email:

oded@tourengine.com

Partners

Next Step Engineering Solutions, LLC

Wisconsin Engine Research Consultants, LLC

Related Projects

Release Date:

10/16/2014