Spark-Assisted HCCI Residential Generator

Technology Description:

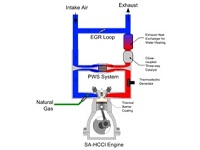

Wisconsin Engine Research Consultants (WERC) and its partners Adiabatics, Briggs and Stratton, and the University of Wisconsin-Madison will develop a generator using an internal combustion engine (ICE) that incorporates an advanced spark-assisted homogeneous charge compression ignition (SA-HCCI) system. Traditional internal combustion engines use the force generated by the combustion of a fuel (e.g. natural gas) to move a piston, transferring chemical energy to mechanical energy. This can then be used in conjunction with a generator to create electricity. SA-HCCI systems achieve combustion by compressing their fuel/air mix to the point of ignition, with a spark helping to initiate the process. These systems run very fuel lean and achieve high efficiency and waste less heat compared to conventional ICEs. In addition, the WERC team will further increase efficiency by incorporating thermal barrier coatings, an advanced boost system, and an optimized low-friction combustion chamber.

Potential Impact:

If successful, WERC’s project will facilitate development and commercialization of economical, efficient, and durable CHP systems for residential use. These advancements support progress toward ARPA-E’s overall goals as follows:

Security:

Innovations developed in this project could help households and businesses become more energy self-reliant and less susceptible to energy-related outages through distributed, local generation of power and heat.

Environment:

Widespread adoption of high-efficiency residential CHP systems could decrease overall primary energy consumption and therefore reduce CO2 emissions associated with electricity generation by up to 10%.

Economy:

Cost-effective natural gas-fueled residential CHP systems could offer consumers lower electricity and heating bills.

Contact

ARPA-E Program Director:

Dr. David Tew

Project Contact:

Prof. Rolf Reitz

Press and General Inquiries Email:

ARPA-E-Comms@hq.doe.gov

Project Contact Email:

reitz@engr.wisc.edu

Partners

Briggs and Stratton

University of Wisconsin - Madison, Engine Research Center (ERC)

Adiabatics, Inc.

Related Projects

Release Date:

10/16/2014