Project Title: Scaled In-Line Processing Facility for Permeability Engineered Nanocrystalline Magnetics

Location: Pittsburgh, PA

Award Amount: $5,000,000

Challenge

CorePower Magnetics is addressing the need for smaller, more efficient power electronics components to enable electric vehicles to charge faster and travel farther as well as to support renewable energy integration and efficiency gains in the electric grid. Large, inefficient transformers and inductors limit system performance. There is a need for domestic manufacturing capability for advanced soft magnetic materials to improve national energy security and reduce reliance on rare earth imports.

Technical Approach

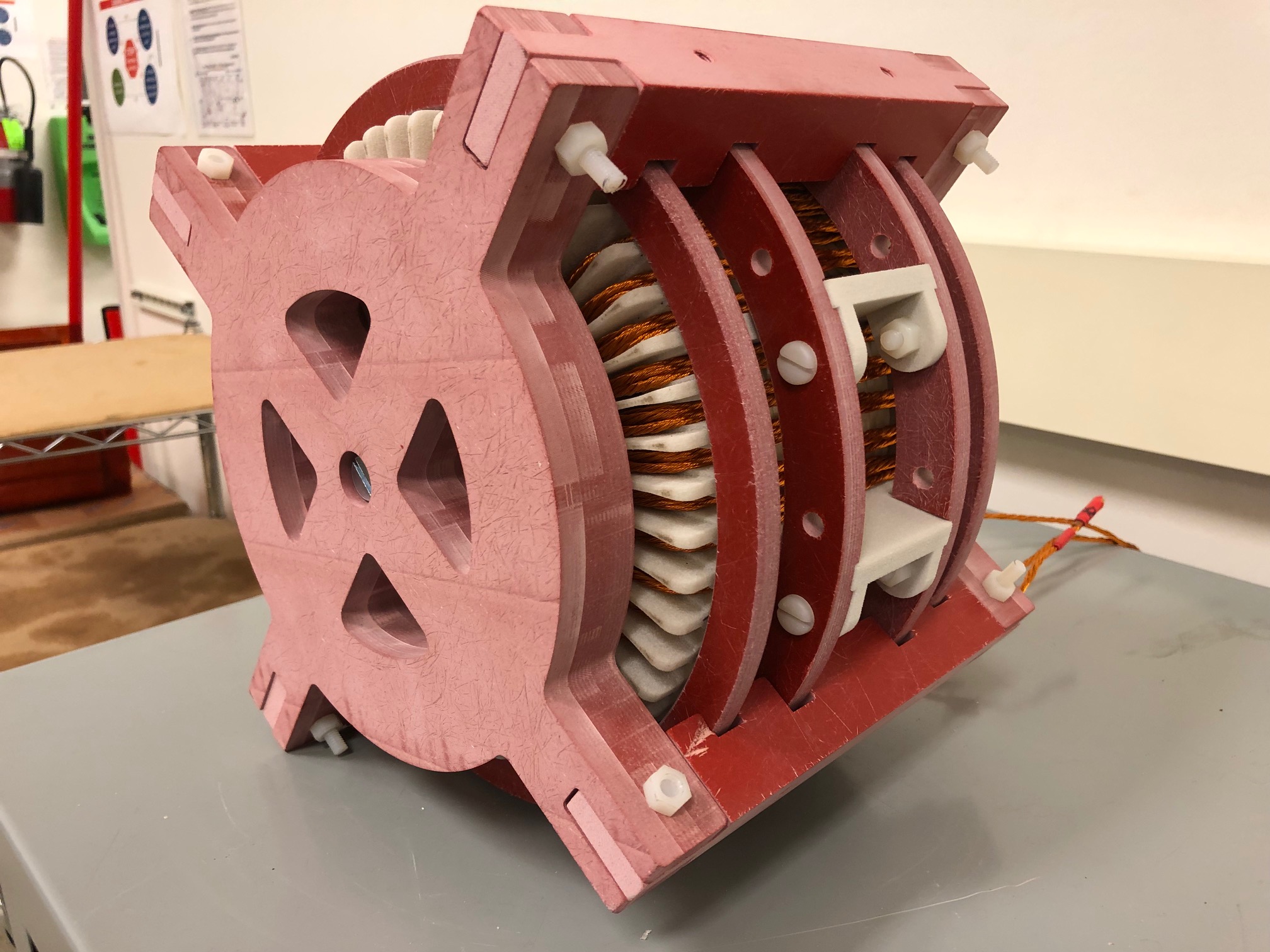

CorePower is using proprietary nanocrystalline magnetic core technology developed over more than 10 years with support from ARPA-E and other Department of Energy offices. The technology combines novel nanocrystalline alloys and advanced processing to engineer unprecedented levels of magnetic permeability and efficiency. The team will demonstrate the manufacturability of the patented process and establish standardized inductors and transformers targeting electric vehicle and renewable grid applications. High power density inductors and transformers will enable high frequency power electronics.

Team

CorePower Magnetics leadership combines deep expertise in both the underlying core technology as well as manufacturing and commercialization experience. Dr. Samuel Kernion, CEO, previously held leadership roles in R&D and operations at Carpenter Technology focused on new product development and commercialization. Dr. Paul Ohodnicki, CTO, is a leading expert in soft magnetics design and processing with over 40 patents. Kevin Byerly, Lead Engineer, has more than 15 years of experience building magnetic components. The team includes research partners from North Carolina State University and the National Renewable Energy Laboratory.

ARPA-E Mission Alignment

Widespread adoption of CorePower's high efficiency inductors, transformers, and motors would catalyze greater electrification of vehicles and improve renewable integration and resilience of the electric grid. CorePower's domestic manufacturing helps improve energy security by reducing reliance on foreign rare earth imports used in today's motors. Grid-scale deployment of CorePower's power electronics components enables utilization of high frequency power conversion systems. These systems are much smaller and more efficient than traditional grid-scale components. Wide-scale adoption would both modernize grid infrastructure and facilitate greater penetration of renewable energy generation. Advanced transformers and inductors translate to improved grid reliability, efficiency, and resilience.