Project Title: Pilot Production for Commercial Sampling of Rare-Earth-Free Iron Nitride Permanent Magnets

Location: Minneapolis, MN

Award Amount: $17,500,000

Challenge

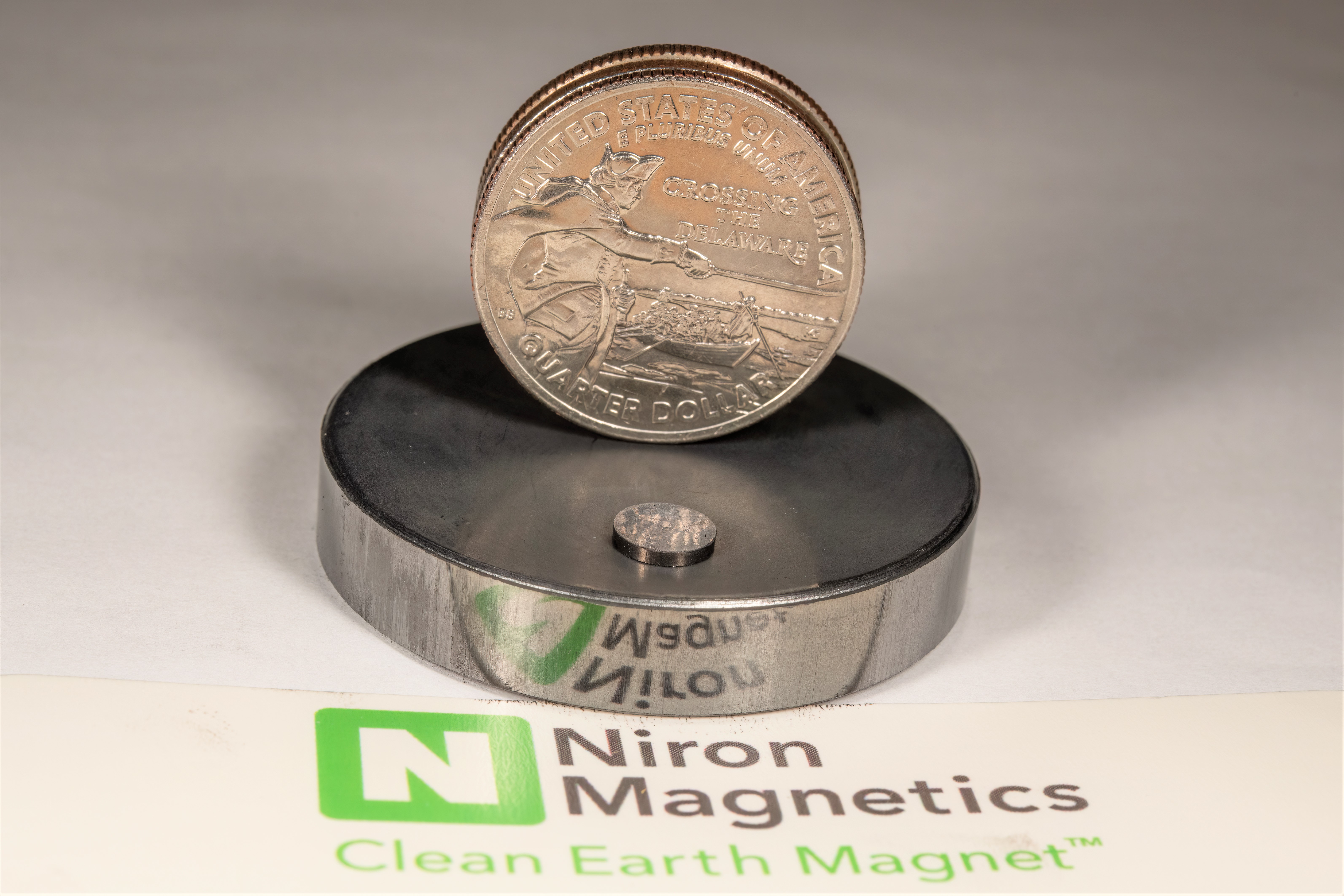

The reliability of the rare earth magnet supply chain is of critical importance for the United States’ transition to a clean energy economy. Niron’s Clean Earth Magnets® (“CE Magnets”), based on the iron nitride compound, are powerful permanent magnets free of critical minerals and made of abundant commodity inputs. As such, they are a path to disrupting dependence on rare earth magnet imports for technologies critical to the U.S. energy transition.

Technical Approach

Niron will achieve pilot-scale proof of concept by demonstrating a manufacturing capacity of thousands of kilograms of permanent magnets per year. Niron will also accelerate customer sampling and support prototypes for product development of climate critical applications. The project will retire the engineering risk of scaling by completing production tool design and preliminary design specifications for a full-scale manufacturing facility.

Team

Niron has assembled an interdisciplinary team with backgrounds in materials physics, metallurgy, and semiconductor technology with support from the public and private sectors. Our leadership has decades of experience in the development and commercialization of new technology. Located in Minneapolis, Niron draws from a deep pool of talent in engineering and manufacturing.

ARPA-E Mission Alignment

This project supports ARPA-E’s mission by: (i) reducing energy-related emissions, including greenhouse gases, by directly reducing magnet production emission and enabling emission reduction technologies including EVs, wind generation, and efficient industrial motors, and (ii) improving the resilience, reliability, and security of U.S. energy infrastructure by reducing reliance on critical rare earth imports and positioning the U.S. as an exporter of a competing magnet technology.