High-Efficiency Energy Converters

Technology Description:

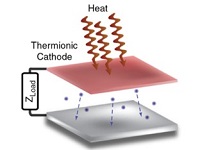

By leveraging advanced microfabrication processes, the team led by Stanford University will develop a scalable heat-to-electricity conversion device with higher performance at a lower manufacturing cost than is presently available to industry. The team’s solid-state conversion device is based on a 20th century thermionic converter design, where an electric current is produced by heating up an electrode to eject electrons across a vacuum gap for collection by a cooler electrode. Historically, thermionic energy converters are limited by heat losses and are costly to manufacture due to the high precision used in their construction. However, by utilizing wafer-based fabrication processes to create a much smaller vacuum gap and enhanced thermal isolation structures, Stanford’s thermionic converter will result in improved device performance, lower manufacturing cost, and a scalability for systems producing Watts to Megawatts of power. The team’s initial focus is on the residential Combined Heat and Power (CHP) applications, but their innovative microfabricated thermionic device could also be used to improve efficiency in high-temperature solar thermal systems as well as convert waste heat from factory equipment, power plants, and vehicles to useful power.

Potential Impact:

If successful, Stanford's energy converters could yield drastic improvements in the efficiency of thermal energy conversion for residential CHP, distributed solar thermal power, and broadly enable heat scavenging.