Advanced Absorption Cooling

Technology Description:

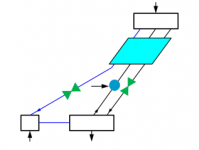

The University of Maryland (UMD) and its partners will utilize a novel microemulsion absorbent, recently developed by UMD researchers, for use in an absorption cooling system that can provide supplemental dry cooling for power plants. These unique absorbents require much less heat to drive the process than conventional absorption materials. To remove heat and cool condenser water, microemulsion absorbents take in water vapor (refrigerant) and release the water as liquid during desorption without vaporization or boiling. UMD’s technology will use waste heat from the power plant’s flue gas to drive the cooling system, eliminating the need for an additional power source. The design will improve upon the efficiency of commercially available chillers by 300%, even though the cost and size of UMD’s technology is smaller. The indirect, absorption cooling system will lower condenser water temperatures to below the ambient temperature, which will ensure the efficiency of power plant electricity production.

Potential Impact:

If successful, UMD and its partners will develop a significantly improved absorption cooling system that can provide supplemental cooling to power plants without consuming water.

Security:

Power plants can maintain energy efficiency by using the team’s absorption cooling technology instead of water cooling when water use is restricted.

Environment:

UMD’s absorption cooling will be powered by waste heat from the power plant’s flue gas. Therefore, the system will not require an additional power source, such as natural gas, which could result in additional emissions.

Economy:

By reducing the size of the system while dramatically increasing its efficiency, UMD’s technology could reduce the cost of using absorption cooling for supplemental power plant cooling.

Contact

ARPA-E Program Director:

Dr. David Tew

Project Contact:

Dr. Bao Yang

Press and General Inquiries Email:

ARPA-E-Comms@hq.doe.gov

Project Contact Email:

baoyang@umd.edu

Partners

Stony Brook University

Texas A&M University

Electric Power Research Institute, Inc. (EPRI)

Related Projects

Release Date:

09/26/2014