Water Recovery for Cooling

Technology Description:

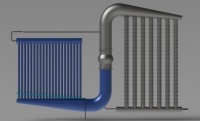

Stony Brook University will work with Brookhaven National Laboratory, United Technologies Research Center, and the Gas Technology Institute to develop a thermosyphon system that condenses water vapor from power plant flue gas for evaporative cooling. The system could provide supplemental cooling for thermoelectric power plants in which the combustion process – burning fossil fuel to produce heat – results in a significant quantity of water vapor that is typically discharged to the atmosphere. In Stony Brook’s system, an advanced loop thermosyphon will allow the liquid and vapor phases to flow in the same direction, and the working fluid (water) is actively managed with a fluid delivery system to create a thin film on the wall of the thermosyphon. This thin film will enable significantly higher heat transfer rates than traditional thermosyphon evaporators that use a pool of liquid. The cooled flue gas condensate is then stored and used for subsequent evaporative cooling when the ambient temperature exceeds acceptable operating limits, such as on a hot day when a dry-cooling system alone could not cool water sufficiently for reuse. In addition to creating a novel design and control architecture, the team will also design innovative, polymer-based components to minimize corrosion from the flue gas. The team estimates its system can capture 320,000 gallons of water per day for evaporative cooling, helping to eliminate the consumption of local water resources for evaporative cooling on high-temperature days.

Potential Impact:

If successful, Stony Brook and its team members will develop a novel cool-storage system that reduces water consumption for power plant cooling by capturing flue gas condensate and storing it for reuse.

Security:

Power plants can maintain energy efficiency by using the team’s technology, instead of using separate water sources for cooling when water use is restricted.

Environment:

The team’s system could reduce water usage for evaporative cooling on hot days, which helps conserve water for other uses.

Economy:

Stony Brook’s design allows the system to operate continuously in a range of climates across the United States, without sacrificing power plant performance, and therefore could be adopted by a large market of power plant operators.

Contact

ARPA-E Program Director:

Dr. Michael Ohadi

Project Contact:

Prof. Jon Longtin

Press and General Inquiries Email:

ARPA-E-Comms@hq.doe.gov

Project Contact Email:

Jon.Longtin@stonybrook.edu

Partners

United Technologies Research Center

Texas A&M University - Kingsville

Gas Technology Institute

Brookhaven National Laboratory

Related Projects

Release Date:

09/26/2014