Hybrid Engine Generator for Residential CHP

Technology Description:

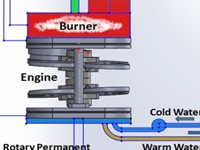

Sencera Energy and Ohio University will develop a novel kinematic Stirling-Brayton hybrid engine using flexure based volume displacement in lieu of a conventional piston-cylinder Stirling engine. A Stirling engine uses a working gas housed in a sealed environment, in this case the working gas is helium. When heated by the natural gas-fueled burner, the gas expands causing a piston to move and interact with an alternator to produce electricity. As the gas cools and contracts, the process resets before repeating again. Advanced Stirling engines endeavor to carefully manage heat inside the system to make the most efficient use of the natural gas energy. The flexure-based design achieves the same function as a piston-cylinder set by simply changing the volume of the working spaces, as opposed to sliding a piston along the interior of a cylinder. The removal of pistons from the design eliminates the need for sliding seals such as piston rings or air/gas bearings, resulting in lower engine friction, less fluid flow loss and fewer dead volumes. It also lowers the potential fabrication cost compared to other heat engines. The proposed kinematic engine design provides easy coupling to existing rotary alternator designs, which allows the use of robust, mature, and cost-effective off-the-shelf alternator technologies and controllers.

Potential Impact:

If successful, Sencera’s project will facilitate development and commercialization of economical, efficient, and durable CHP systems for residential use. These advancements support progress toward ARPA-E’s overall goals as follows:

Security:

Innovations developed in this project could help households and businesses become more energy self-reliant and less susceptible to energy-related outages through distributed, local generation of power and heat.

Environment:

Widespread adoption of high-efficiency residential CHP systems could decrease overall primary energy consumption and therefore reduce CO2 emissions associated with electricity generation by up to 10%.

Economy:

Cost-effective natural gas-fueled residential CHP systems could offer consumers lower electricity and heating bills.

Contact

ARPA-E Program Director:

Dr. David Tew

Project Contact:

Dr. Russell Jewett

Press and General Inquiries Email:

ARPA-E-Comms@hq.doe.gov

Project Contact Email:

rusty.jewett@sencera.com

Partners

Ohio University

Related Projects

Release Date:

10/16/2014